Nice.

Your screw holes are inside the gasket perimeter, so I guess that will be the weak point…

Nice.

Your screw holes are inside the gasket perimeter, so I guess that will be the weak point…

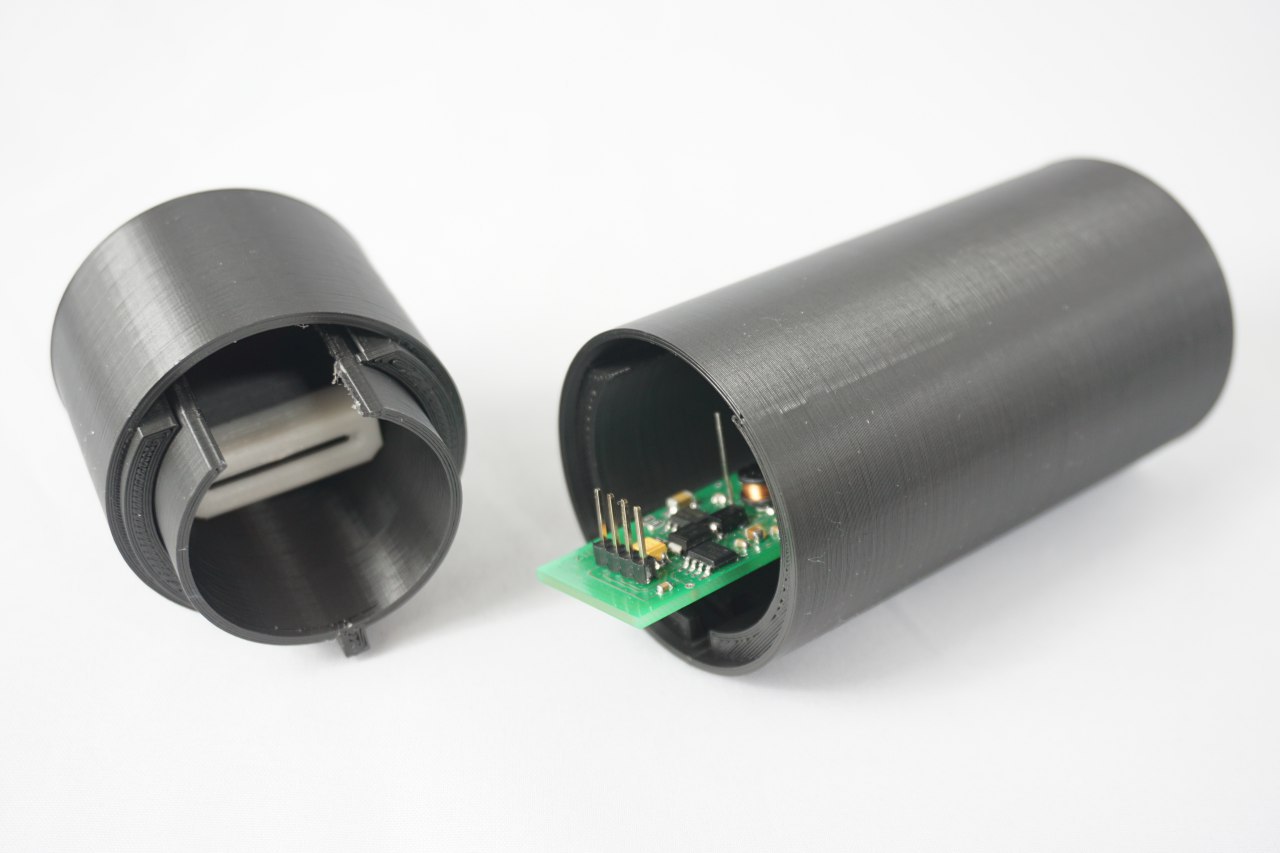

Sadly… yup. In order to keep the overall size down I’ve run the 4 screws through the PCB which makes gasketing them difficult. The screws and nuts are both recessed, and I hope that pulling them tight enough against the PETG will help keep water out. The worse problem is the antenna egress, which similarly isn’t very well gasketed, and which is why I have it facing downwards.

This solution is hoping to provide some weather proofing, but if anyone was looking for underwater LoRaWAN this probably isn’t going to help

Hi guys!

Just want to share my new work!

I had printed a network device case. For the project I used a 3D printer Picaso Designer 3D and PLA plastic from U3Print.

Not my creation.

Sources and instructions : https://framagit.org/xbranca/peacock_spider_the_solder_assistant

One more work. I modeled and 3D printed an inclinometer body. I will use it as an exhibition sample for their display booth. The body was printed on a Picaso Designer X Pro with U3Print PLA material.

Hi guys!

I noticed that many of my friends can’t decide which Anet 3D printer to buy: A6 or A8 and can’t understand what the difference between them. I just want to share my experience with you, maybe it will help someone to choose a fit 3D printer…

The A8 was my first 3d printer, not sure if this was the right choice for a first-time purchase, but I certainly learnt a lot. If you have some budget to spare, I would probably consider buying the A6 or a ready-to-use 3D printer.

Here are some of the main pros and cons:

Both are DIY kits and it will take time to assemble and get them to work. I know of many people who changed 15-30% of Anet’s original components to get them to work (and to make sure they won’t go on fire). Personally, I didn’t encounter such significant issues. In addition to the printer, I purchased a glass bed, a set of nozzles, fans as well as a set of spare bearings and belts. (Didn’t have to use the spare parts yet).

Anet A8 is more popular and has a large number of useful mods & upgrades (eg. check out thingeverse.com). It also has a larger build volume, but that’s probably where its advantages are ending. The A6 is sturdier, has an improved motherboard, a more convenient control system and a faster hotbed. My friend’s Anet A6 prints at the same quality that my upgraded Anet A8 does.

So, it’s up to you to decide. If you’re more the tinkering kind and need a larger build volume, go for Anet A8. If you want a more convenient and reliable machine, plus have some extra budget, go for Anet A6 or an entirely different machine, eg. Creality Ender 3 is affordable, but almost works out of the box.

Here’s a good comparative review of both with a video on how the two are assembled.

You are aware this forum is for The Things Network and not a generic 3D printing forum? We do allow things to veer of topic a little but please keep things focused. I think 3D printer buying advice is best left to other sites where larger numbers of printers can be compared compared. Every printer has pros and cons and it depends on the user and requirements which is the best fit.

With a nod to Jacks comment above about keeping thread TTN focused I thought this one worth breaking rules and sharing this one… desperate times desperate measures.

I know many of us have 3D Printing capacity and/or are members of maker spaces with some of the additional tools/equipment. Just be sure to limit group sizes and keep social distancing if collaborating with others on a production run. These are imperfect and clearly not certified but in some parts of the world and some circumstances may be make a real difference and save lives/reduce infection risk.

Hi everyone,

Not sure if anyone can help, but I am looking for an outdoor housing for 2 different setups, the first is for a raspberry pi with dragino type shield, will likely be a RFM95 breakout initially and then the second is for a esp32 based lora board, like the TTGO, just without display.

I cant seem to find any designs for either wallmount or pole mounting and unfortunately my 3d design skills are not great, does anyone perhaps know if such models are available to download somewhere?

Regards

Got a 3d printer, spare time in ‘lockdown’ and a raspberry pi going spare? Grab a Pi Camera and try this:

Paper & link to full article here: https://www.osapublishing.org/boe/abstract.cfm?uri=boe-11-5-2447

Useful for inspecting those experimental sensor/LoRaWAN pcbs?

Added link: https://openflexure.org/projects/microscope/

I don’t think so. The camera is on the bottom side and probably needs very close distance to focus.

I wonder their minimum price of £15. That will not even get you the Pi camera V2 (Pi not included) and I presume also an additional lens will be required.

Hi there. Really glad do find this thread and all these tips for 3d printing. Wanna share the tips that helped me with FlashForge Finder:

For using a FlashForge Finder: When inserting filament, don’t stop when you feel a little resistance, keep pushing for about 2 inches 40-50mm) until you can’t push any more.

If you get the “Something went wrong during slicing” error, try changing the location of your saved .fpp and/or .gx printing files. Mine were initially going to the MacintoshHD… changing the file location to Desktop fixed the issue.

To determine if a model is causing a slicing error, load one of FlashPrint’s internal testing models under File/Examples - if the file prints, the issue is with your model OR where you’re exporting the .fpp and/or .gx printing files, not with the FlashPrint software.

The sources that I find useful:

https://all3dp.com/2/3d-print-quality-12-tips-on-how-to-improve-it/

I didn’t read the filament article (yet) but the following is remarkable:

“<title> (Summer 2022)” and then “Last updated: December 13, 2021”

Hi. Thanks, everybody for sharing the slick information. I am just a beginner in 3d printing and looking for some support on 3d forums. When I was looking for my first printer I also searched for advice and reviews. I purchased one from this review 7 Best 3D Printers under $200 Reviewed in Detail (Summer 2022).

You are saying that Many of the objects require a lot of support to be added, in there. Is there a way to minimize the supports in order to save material?